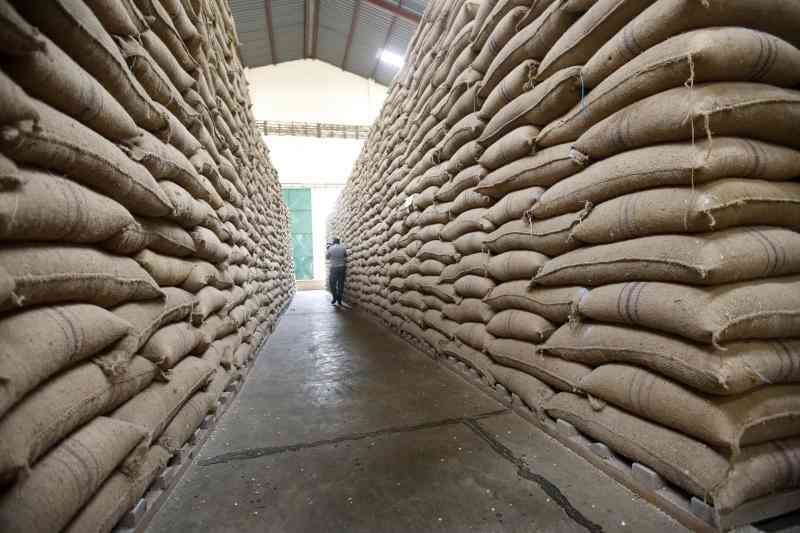

Most warehouses for storage of farm produce are said to be substandard, which is now being blamed for increased post-harvest losses in the country.

The Warehouse Receipt System Council (WRSC) says it cannot certify these warehouses as they are not up to the stipulated standards.

This is why the council is proposing standardisation in construction to ease the certification challenges.

The challenge of substandard or adequate warehouses for storage of farm produce has been captured in the latest study conducted by the Financial Sector Deepening (FSD) Kenya and the Agricultural Finance Corporation (AFC).

The Warehouse Receipt Financing Feasibility Study found that most smallholder farmers still prefer to store their produce on their farms at 94 per cent. The rest is stored in government or private warehouses.

The major reason for many farmers not using warehouses is the cost consideration, with 46 per cent of the respondents admitting to not making use of the service. Four in 10 smallholder farmers also reported having never tried using a warehouse.

These high costs are directly related to the quality standards that warehouse investors or operators need to adhere to get certification from the WRSC.

A major investment, as noted by a Senior Agricultural Officer, State Department for Agriculture Benson Kamau, is the dryer.

“Cereals, particularly maize, require to be stored in a particular moisture content to avoid aflatoxin, and this calls for constant investment in dryers whose cost is out of reach of many smallholder farmers,” he said.

Mr Kamau noted that losses associated with poor post-harvest practices stand at 40 per cent, with the biggest challenge being access to warehouses.

WRSC Registrar and Chief Executive Lucy Komen said in some crops, the post-harvest loss is more.

“When you go each crop, like potato, the post-harvest losses are a bit higher due to lack of storage facilities,” she said.

Ms Komen pointed out that the storage facilities that have been built by the private sector and national and county governments, in partnership with development partners do not meet the set standards.

As such, they cannot be certified for use by farmers. “We have seen a lot of warehouses, more than 100, that we cannot certify,” she said.

Ms Komen admitted that some of the requirements to warehouse investors and owners to bring them up to standard are costly.

“This also includes warehouses that were built by the government or sponsored by development partners,” she said.

“We hope that going forward, for any warehouse structure built for storage of food, investors will first put into consideration the quality standards required before starting to build.”

Some of these costly requirements for warehouse operators before certification include insurance coverage in case anything happens to the stored commodity.

This includes insurance against theft, fire, or natural disasters, considering the produce may rot over time. This is above the necessary business licences and insurance covers.

Agricultural Finance Corporation (AFC) Managing Director George Kubai said smallholder farmers in the country lose about 30 per cent of their produce once harvested.

The majority of this (20 per cent) is lost at the farm gate while the rest is during marketing.

He further noted that due to inadequate storage facilities, especially with the maize crop the waste ranges from 40 to 60 per cent, a situation he described as a serious concern.

“When we talk of maize crop, this is a staple food, yet the farmer is experiencing losses of 40 to 60 per cent, then you realise how dire the situation is,” said Mr Kubai.

FSD Kenya looked at rice, coffee, maize, pulses (dry peas, beans and lentils) and wheat as it sought to gauge the possibility of a warehouse receipt financing model for smallholder farmers.

Of these, only coffee is stored in private warehouses. A majority of farmers store their maize, wheat, rice and pulses on their farms.

The reason for storing these products closer to them is consumption, represented by 94 per cent of smallholder farmers, followed by 36 per cent - who store for planning the next season - and 32 per cent for speculation purposes.

While 73 per cent of the respondents noted that they would prefer having their produce in a warehouse receipt system, 75 per cent said they would rather handle their harvest by themselves.

“The coffee and rice value chains have a low demand for warehouse receipt system on account of their relatively formal structures and should not be considered for piloting the warehouse receipt financing product,” reads the study.

The National Cereals and Produce Board (NCPB) is the major player in warehouse services with certified facilities in Kitale, Nairobi, Meru, Eldoret and Nakuru.

The Standard Group Plc is a multi-media organization with investments in media platforms spanning newspaper print

operations, television, radio broadcasting, digital and online services. The Standard Group is recognized as a

leading multi-media house in Kenya with a key influence in matters of national and international interest.

The Standard Group Plc is a multi-media organization with investments in media platforms spanning newspaper print

operations, television, radio broadcasting, digital and online services. The Standard Group is recognized as a

leading multi-media house in Kenya with a key influence in matters of national and international interest.