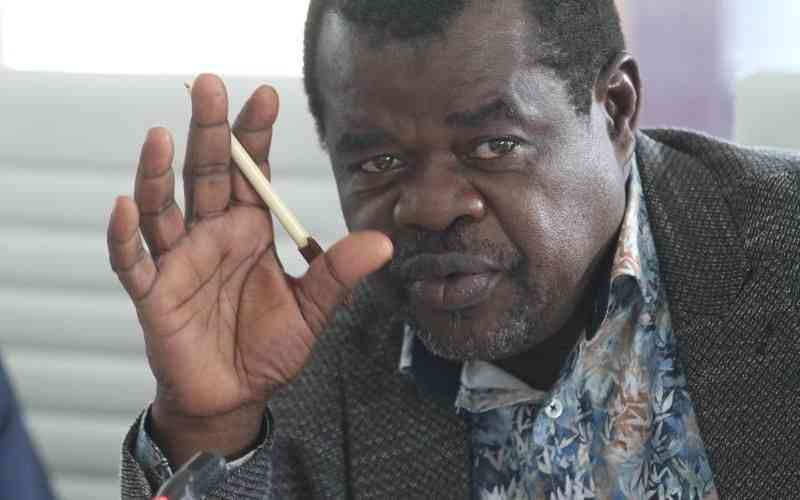

He was a simple man making a simple living in the blue-collar industry; Jua kali to be specific. But focus and vision propelled him to where he is today. What started as a simple initiative by Stephen Obewo aimed at tapping into the rapidly growing construction industry has started paying off for the jua kali artisan in Siaya County. Stephen did not imagine that his small venture manufacturing nails, barbed wires, chain links and fencing wires would grow rapidly. The 43-year old CEO of Nambole Traders Company which has over 30 employees is changing the region one nail at a time. He shares his journey that began one year ago.

What kind of machines do you use to make nails?

Not just nails but also barbed wires and chain links. We have a wire drawing machine used for straightening and adjusting wires before taking them to a machine to make nails. The wire nail machine that makes nails from two to four inches produces a bag of 40 kilos of nails in a span of 24 hours. I also have a chain link machine that makes 80 fences and chains from four to 10 feet in 24 hours and a barbed wire machine that makes two types of wires which are 480 and 610 metres respectively. The machines which run on electricity, operate day and night.

How much capital did you need?

I started with Sh1 million. This I raised from my past hustle in Juakali where I did a lot of businesses in scrap metal, fabrication works and other mechanic works. I had also acquired some tractors which I leased out to farmers during ploughing season. Additionally, I do fabrication works and now and then, get contracts from construction projects; for example, I have done fabrication for the chairs used in the local university. All that helped when I was raising capital.

How did you decide to start a nail making company?

I developed interest during my days at the Juakali as a plant mechanic. I had longed for this opportunity for too long. And whenever I attended trade fairs, I would concentrate a lot on the ones which had manufacturing projects. I had also visited several companies to learn more about the manufacturing business and visited countries like China and India for benchmarking once I realised there was a real opportunity in nails, chain links and barbed wires.

What are some of the challenges you initially faced when starting off?

Getting skilled labour when starting off was a big challenge. I started off with only three workers before expanding the number because getting those who could operate the machines and maintain them was a big challenge. Also getting raw materials was a challenge. Further, I did not have this crucial machine known as a drawing machine to draw the nails and make them when I began. But once I bought it, we could do the drawing for ourselves and our work became easier. We were now able to draw the nails into whatever sizes we want before channelling them to a machine that makes nails. We now have two drawing machines.

What challenges do you continually face?

The greatest challenges are the lack of raw materials to enable a steady supply of products for the growing market. There is a growing demand for our products and a huge market to tap but we also have a limited number of machines. Another problem is that some people believe the quality of local products is poor and therefore would rather go with the big brand names. They do not believe a local company can give them quality. We however make quality nails, fencing wires, chain links and barbed wires and there is no difference between what we make and what those big companies make. We may be better.

My workers work in two shifts, day and night and now with the growing demand, I will be forced to expand my business in the coming months and among the things that we will need to increase is the number of staff.

What are some of the business mistakes you have made?

I am still a year old in the business so I may not have made so many mistakes, but I will definitely say the greatest goof I made was starting off the business without a Kenya Bureau of Standards (KEBs) certification. This led to them seizing our products. I had worked for two months without their certificate. We are now compliant and things have been smoother since them.

Stay informed. Subscribe to our newsletter

What advice would you give young people hoping to get into entrepreneurship?

I urge them to be bold enough and once they decide to do something they should focus on it and channel all their energy in it. They should not be afraid at all but also they must be ready to risk and be patient. Above all they must be ready to work extra hard.

Where do you sell your products?

I have a market for my products in the county and also in neighbouring Kakamega, Kisumu, Homa Bay and Bungoma. When you visit the neighbouring counties you will get our products. We are trying to compete with giants with already made brand names. I am happy that in this short time we have done well in the market because of quality.

How much do you sell your products?

I sell 1kg of nails at a retail price of Sh150 and wholesale is Sh110. The chain link per foot is Sh450 for wholesale price and Sh500 (retail). For barbed wire, 610 metres go for Sh4,200. Barbed wire measuring 480 metres fetches Sh3,200 (wholesale) and Sh3,500 (retail).

Prices vary with the rise and fall of the dollar.

The Standard Group Plc is a

multi-media organization with investments in media platforms spanning newspaper

print operations, television, radio broadcasting, digital and online services. The

Standard Group is recognized as a leading multi-media house in Kenya with a key

influence in matters of national and international interest.

The Standard Group Plc is a

multi-media organization with investments in media platforms spanning newspaper

print operations, television, radio broadcasting, digital and online services. The

Standard Group is recognized as a leading multi-media house in Kenya with a key

influence in matters of national and international interest.

The Standard Group Plc is a

multi-media organization with investments in media platforms spanning newspaper

print operations, television, radio broadcasting, digital and online services. The

Standard Group is recognized as a leading multi-media house in Kenya with a key

influence in matters of national and international interest.

The Standard Group Plc is a

multi-media organization with investments in media platforms spanning newspaper

print operations, television, radio broadcasting, digital and online services. The

Standard Group is recognized as a leading multi-media house in Kenya with a key

influence in matters of national and international interest.