×

The Standard e-Paper

Home To Bold Columnists

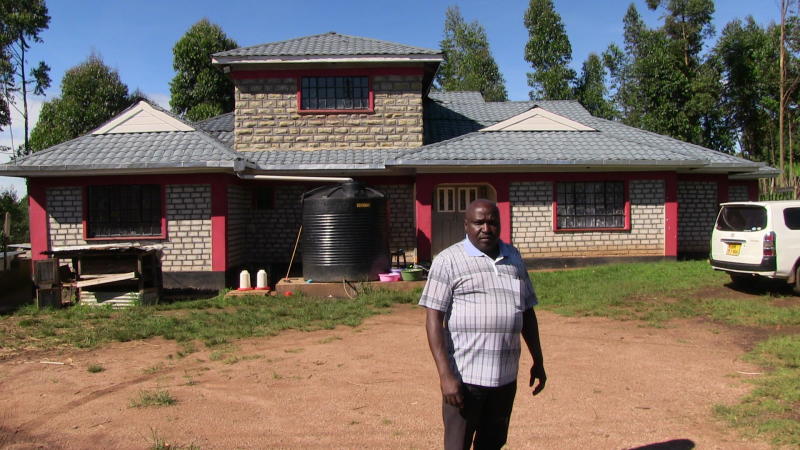

In 2014, Francis Tonui wanted to build his dream house.

But when he visited a contractor to find out how much it would cost, he was taken aback when he was presented with a Sh16 million Bill of Quantities.