By MOSES MICHIRA

Kenya: Today, a family somewhere in New York City will walk into a store and purchase towels.

They will take time to look at those made from quality cotton before settling on one.

What they will not know is that it may have been manufactured some 8,000 miles away in Kenya using the best cotton that was harvested in late 2011 from a half-acre farm in a Nyahera, outside Kisumu.

The towel would most probably bear international design labels like Marks & Spencer or BHS, and it will be on Spring Sale, which involves a set containing four pieces including one for bath, hand and two face towels selling at Sh3,000 ($35).

On an ordinary day, the price is Sh4,250 ($50), all weighing a kilo and half.

If the family picks up the pure white set of towels after a bit of convincing from a salesperson, that would be the end of a two-year journey that began when the farmer ploughed his land and planted the cotton seed. The salesperson is among a dozen workers employed at the store, including the driver who brought in the consignment from the port. Another American firm shipped the container from Vietnam where the towels were manufactured in a garments factory that the store in New York has outsourced the entire production to.

A Kenyan firm making similar towels and is employing the latest technologies in its Kitengela plant handles 1,800 bales of cotton a year, employs 300 people on full time basis.

But Kenya exports about half of the 40,000 bales of cotton lint that was produced in 2011. In the same year, 20,000 people were employed in the Kenyan textile industry whose exports to the US under the Africa Growth Opportunity Act, worth about 21 billion. What it means is that Kenya exported 20,000 jobs, in the textile processing alone, when it sold half of it cotton produce.

Assuming the entire 20,000 bales of cotton, weighing four million kilos, were exported to Vietnam, the country may have unconsciously created as many jobs for the Vietnamese in a country where only two in a hundred people do not have jobs.

The 1.8 per cent unemployment in Vietnam against the 54 per cent in Kenya is incomparable.

Each of the workers earn a monthly salary that is equivalent of Sh6,500. They are all employed on a full-time basis as the manufacturer tries to meet the huge order from his client. The entire towel-making process takes at least four months.

The towels will form part of the Sh1 trillion worth of garments that Vietnam exported to several countries that year.

But the cotton lint was imported into Vietnam from Kenya after the ginnery was unable to find a ready market because the local textile companies collapsed in early 1990, and everyone buys imported clothes, including the Government.

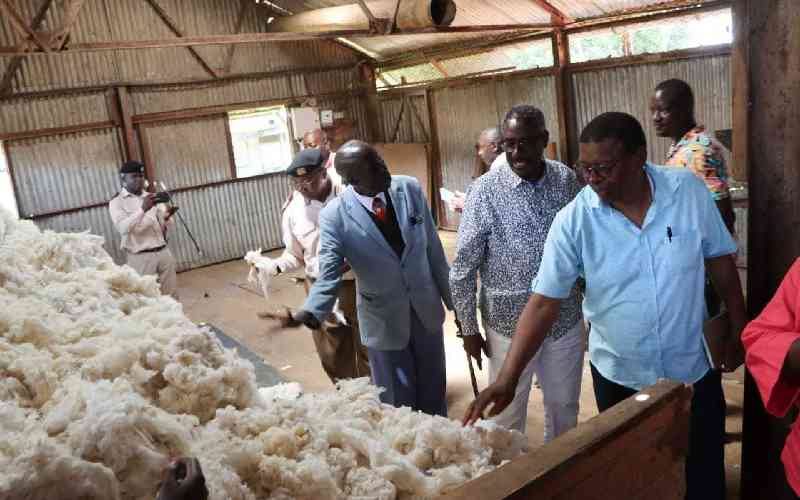

There are seven people employed in the ginnery on a temporary basis, including the driver who brings in the raw cotton after it has been harvested.

Stay informed. Subscribe to our newsletter

Only a quarter of the 1,000 farmers, who used to grow cotton for the ginnery in the 80s are still producing the crop.

Their involvement at the ginnery is, however, one-off and the seven employees could be called in after the next round of harvesting after two weeks.

In total, there are 260 people, who were directly involved in producing the cotton lint that was exported to Vietnam at Sh36,000 for a 200kg bale.

Back at home, however, the farmer who delivered the cotton to the ginnery after tending the crop for six months was paid Sh72,000 for the 1,800kg of the raw produce.

Of this, the ginnery extracted 600kg of pure cotton, and nearly one tonne of seedcake that would be used to make animal feeds.

The animal feeds miller has installed state-of-the-art machinery and requires just ten people, but fortunately on a full-time basis.

On the whole, the cotton value chain has created 270 jobs in Kenya, most of them farmers while only a handful are employed in the value addition as temporary hands, each earning about Sh200 a day.

That is a hypothetical case, which closely mirrors the Kenyan cotton industry, which experts say has the potential to create about a million jobs.

The Standard Group Plc is a

multi-media organization with investments in media platforms spanning newspaper

print operations, television, radio broadcasting, digital and online services. The

Standard Group is recognized as a leading multi-media house in Kenya with a key

influence in matters of national and international interest.

The Standard Group Plc is a

multi-media organization with investments in media platforms spanning newspaper

print operations, television, radio broadcasting, digital and online services. The

Standard Group is recognized as a leading multi-media house in Kenya with a key

influence in matters of national and international interest.

The Standard Group Plc is a

multi-media organization with investments in media platforms spanning newspaper

print operations, television, radio broadcasting, digital and online services. The

Standard Group is recognized as a leading multi-media house in Kenya with a key

influence in matters of national and international interest.

The Standard Group Plc is a

multi-media organization with investments in media platforms spanning newspaper

print operations, television, radio broadcasting, digital and online services. The

Standard Group is recognized as a leading multi-media house in Kenya with a key

influence in matters of national and international interest.